|

|

|

|

|

|

|

|

| Aqueduct construction 1927 |

OVERVIEW

COMMENCEMENT IN 1927

The construction of the Silvan Reservoir commenced

in June 1927, following completion of the outlet conduit, and storage of water began in 1931. The project began under the

supervision of the Board's engineer Alexander Kelso, and continued under FM Lee after 1930. Plans for the design of the project

were produced by I.M. Sutherland, Designing Engineer, and EG Ritchie, Engineer of Water Supply, was responsible for the overall

management.

OUTLET CONTROL TOWER

This

is located in the reservoir, and is an oval-shaped concrete structure featuring a distinctive Egyptian design reflecting a

similar architectural theme as the O'Shannassy Inlet Tower. Unlike the O'Shannassy Inlet Tower this tower features straight

rounded columns, a low decorative wall, and two wells in which the water hydraulics system internal valve controls are located.

The external valves are now operated mechanically, but the ratchets once used to turn the valves by hand are still located

in the tower.

The outlet control tower was constructed prior to commencing

the dam wall, in 1926. It was built with two separate shafts, each with 12 inlet valves operated by a water hydraulics system.

Water was drawn from the reservoir through two 54 inch diameter popes connected to the outlet tower and discharged into a

dissipate basin below the embankment and them on to the outlet channel to connect at Mt Evelyn with the O'Shannassy Aqueduct

(enlarged to take 200 million gallons a day).

EXCAVATION

Excavation

of the corewall trench began in 1928 using three stream driven caterpillar mounted excavators burning wood rather than coal.

According to Kelso, the corewall was of an unusual design, involving impervious material and a drainage system with three

wells of three feet diameter extending vertically from the top of the wall. The wells allowed seepage to drain into a gallery

in the wall, just below the natural ground surface, then into an outlet culvert. Hollow corewalls were expensive to build

and the only other similar corewall construction was in a Mexico dam.

MECHANIZED

EQUIPMENT

The construction of the dam involved extensive use of mechanised equipment, replacing manual

and horse power wherever possible to maintain rapid progress. This represented 'spectacular advances' in techniques since

the building of the sewerage system at Spotswood in the 1890s, and 'cheap and effective methods of moving these vast quantities

of materials were at the heart of the project'. The equipment included steam - powered excavators, locomotives, rollers, and

cranes. In addition, the Board purchased electricity from the SEC for its stationary plant such as the compressor, crushers,

cableway, ropeway, pumps and lighting.

BORROW PITS

In the

borrow pits, the Board acquired three new steam shovels, two manufactured by Ruston and Hornsby (Australia) Pty Ltd and the

third by A.T. Harman of Port Melbourne. The latter was the largest steam shovel constructed in Australia at that time. In

addition the Board used two Fordson steam locomotives for transporting the earth by rail to the dam wall. In total the Board

purchased seven steam locomotives for the site from Perry Engineering Co. South Australia. A 16 ton traction engine was hired,

and used with an 8 ton road roller with special grooved rollers to compress the earthfill as it was deposited on the wall.

1936 REPORT

In reporting on the completion of

the dam, the Board concluded that 'It may be said to constitute a notable advance in engineering progress' and, at 271,691

pounds less than the lowest tender received, was a 'striking illustration of economy'. In 1936, after more drought conditions,

the Board reported that the Silvan 'has been a tower of strength in maintaining the supply of water under these unusual conditions'

and without it Melbourne would have been almost without a water supply.

DAY

LABOUR

The Board employed day labour for the job, with men and equipment able to be transferred from the

nearly complete O'Shannassy Reservoir. The lessons in industrial relations learnt at O'Shannassy were applied to Silvan, and

free accommodation was provided for about 200 men and married quarters for anther 15. The main camp was located at the northern

end of the dam wall, on the opposite side of Stonyford Road to the Staff Camp. Water, sewerage and garbage services were provided,

with water being pumped from Stoneyford Creek to a service basin. The camp also has a private telephone exchange with 30 lines.

TRANSPORTING OF MATERIALS

There were three

principal methods of moving raw materials to the site:

- Aerial Ropeway (8 km from the railway siding at Mt Evelyn, terminating at the crushing plant)

- Aerial Cableway (about 1 km, starting at the,crushing plant, ending at the dam wall)

- Steam Tramway (2 km, starting at the Quarry, and ending at the crushing plant)

Smaller tramways, and a network of unsealed management roads criss-crossed the site,

An excellent illustrated article

titled "Reservoir in the Hills - building of the Silvan Dam", was published

in the Melbourne Argus newspaper on Feb 15, 1930. The archived on-line version may be viewed at

http://trove.nla.gov.au/ndp/del/article/4068842?searchTerm=silvan%20dam&searchLimits=l-title=The+Argus+%28Melbourne%2C...%7Ctitleid%3A13

|

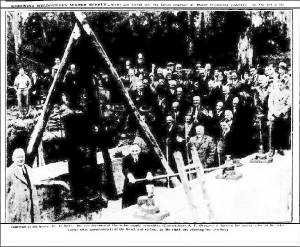

| Official opening July 8 1931 (from Argus) |

|

|

|

|

|

|

|

|

|

|

|

|

Thanks for dropping by and taking a look at my Project! I'd like to hear from you with any comments

or reactions - please Email to Bob Padula

|

|

|

|